No 16 Jalan Biola 33/1

Elite Industrial Park

Seksyen 33 Shah Alam

Hotline

+603 5131 6811

+6019 310 9162

History

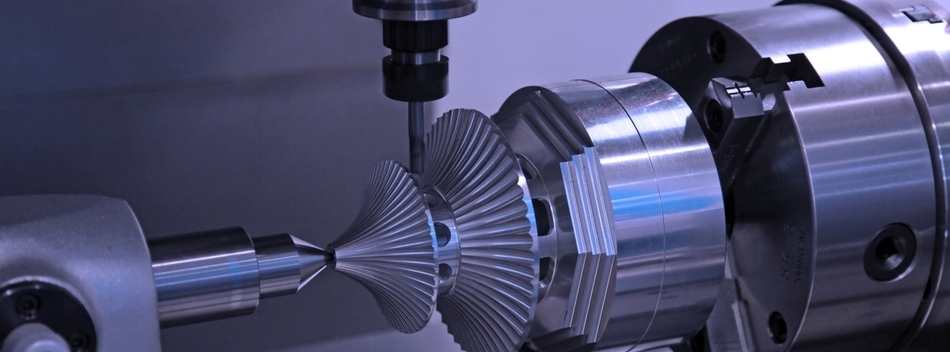

As computers entered the industrial world in the late 1960s, naturally the concept of Computer Numerical Control (CNC) took shape with the addition of Computer Aided Design (CAD) and Computer Aided Machining (CAM) technologies.By the late 1980s, CNC machines were recognized as the industry standard.

Why we use it

It doesn’t really matter what type of component or tool you need, the right CNC machining devices in the hands of a skilled professional can do the job. Whether you’re using a prototype design or a specific mold with steel, metal, brass or even plastic, CNC machining techniques will bring your part to life. On top of the versatility, CNC precision machining produces components with nearly perfect accuracy with each repetition.

Use the right company

The advantages of CNC precision machining are obvious and this technology is also a time-tested technique. However, it doesn’t come easy. Make sure the provider you choose is experienced in a number of industries.

Some CNC precision machining providers may not have access to all the latest tools or the right technologies for every industry, giving them a very narrow focus. The best providers will be able to take their customers from concept to finished part and offer money- and time-saving advice every step of the way.

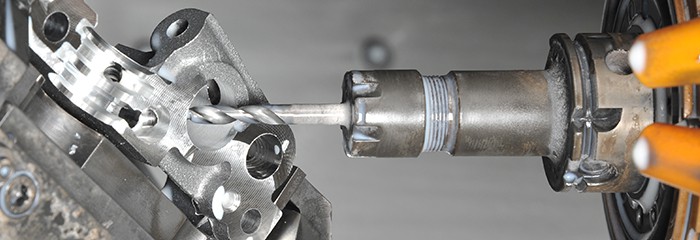

From the regular household appliances we use in our day to day life to the high tech gizmos we use have a common component in them – A Fastener. Fasteners though not visualized by us directly or even thought of, play a vital role in our day to day life. Be it from, holding the chairs and tables we sit on, be it the automobiles we travel, every inch of what we use is held in place by means of a Fastener.

We mainly use a fastener for a non-permanent joint. What do we mean by a non-permanent joint? A joint that can be removed or dismantled without the destruction or damage of the joining components can be termed as a non-permanent joint.

A welding joint or riveted joint can be termed as a permanent joint, which if required to be removed tends to damage or destruct both the joining components as well as the joint itself.

The basis of a fastener is basically a screw thread. – The male part is basically the screw with an external thread and the female part is a hole with an internal thread. The female part can also be a nut. Here are some ways by which a fastened joint can be created.

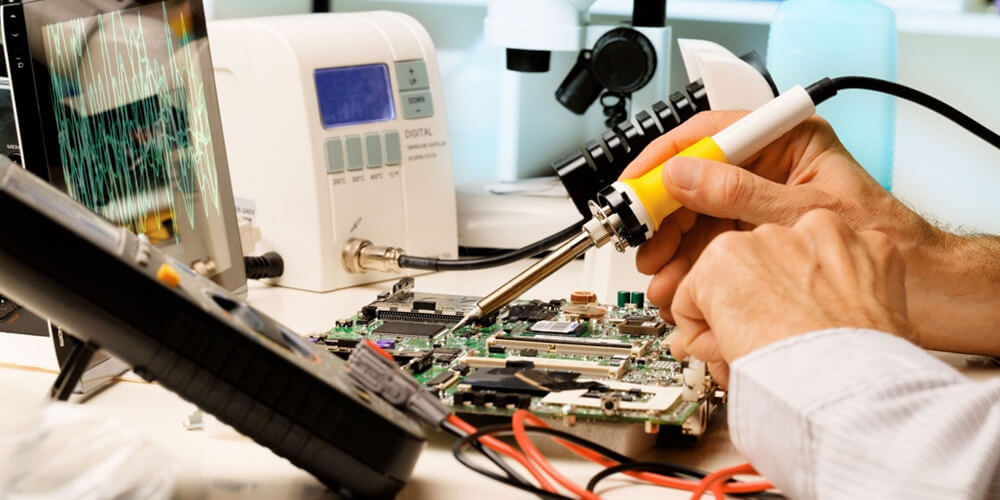

Hardware Engineering is the process of designing, developing, testing and producing computer systems and various physical components related to computer systems. With the advent of technology and advances in R&D, the scope of hardware engineering has been expanded to include hardware devices enabling embedded software engineering in non-computer devices.

In embedded systems, hardware engineering comprises of the process of design and development of all electronics related hardware such as sensors, processors and controllers. The scope of hardware engineering is limited not just to the designing and development of computer or embedded systems, but also to integrate the various devices for the functioning of the entire business system.

With the advent of technology and advances in R&D, hardware engineering is now prevalent in newer fields such as mobile computing and distributed systems, computer vision and robotics, etc.

Mechanical engineering is a diverse subject that derives its breadth from the need to design and manufacture everything from small individual parts and devices (e.g., microscale sensors and inkjet printer nozzles) to large systems (e.g., spacecraft and machine tools). The role of a mechanical engineer is to take a product from an idea to the marketplace. In order to accomplish this, a broad range of skills are needed.

The mechanical engineer needs to acquire particular skills and knowledge. He/she needs to understand the forces and the thermal environment that a product, its parts, or its subsystems will encounter; to design them for functionality, aesthetics, and the ability to withstand the forces and the thermal environment they will be subjected to; and to determine the best way to manufacture them and ensure they will operate without failure.

Perhaps the one skill that is the mechanical engineer’s exclusive domain is the ability to analyze and design objects and systems with motion. To put it simply, mechanical engineering deals with anything that moves, including the human body, a very complex machine.

Mechanical engineers learn about materials, solid and fluid mechanics, thermodynamics, heat transfer, control, instrumentation, design, and manufacturing to understand mechanical systems. Specialized mechanical engineering subjects include biomechanics, cartilage-tissue engineering, energy conversion, laser-assisted materials processing, combustion, MEMS, microfluidic devices, fracture mechanics, nanomechanics, mechanisms, micropower generation, tribology (friction and wear), and vibrations.

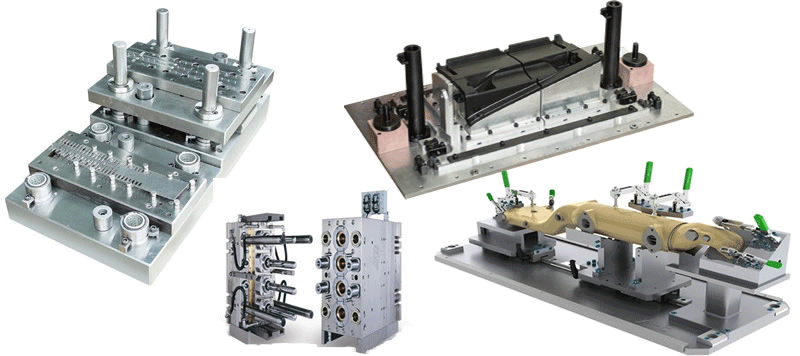

Tooling process is an essential part of the manufacturing process, but many companies are uncertain of the best method of production and what they should be paying. In this month’s blog, we address some common questions on tooling, including what it is, why it’s important and what it costs.

What Is Tooling Process?

Tooling is the process of designing and engineering the tools that are necessary to manufacture parts or components. There are many different types of tooling, of which the most common are: work holding tools, such as jigs and fixtures; cutting tools for milling and grinding machines; dies for cold forming, sheet metal, forging and extrusion machines; and welding and inspection fixtures.

Why Is Tooling Important?

The quality of a finished part, its properties, the speed and accuracy with which it can be produced and the repeatability of manufacture in high volume production runs, all depend on the precision and characteristics of the tooling. So for the best parts, tooling needs to be designed and engineered to the highest quality.

Special Dies and Tools, Die Sets, Jigs and Fixtures, and Industrial Molds Establishments commonly known as contract tool and die shops and primarily engaged in manufacturing, on a job or order basis, special tools and fixtures for use with machine tools, hammers, die-casting machines, and presses. The products of establishments classified in this industry include a wide variety of special toolings, such as dies; punches; diesets and components, and subpresses; jigs and fixtures; and special checking devices.

Establishments primarily engaged in manufacturing molds for die-casting and foundry casting; metal molds for plaster working, rubber working, plastics working, glass working and similar machinery are also included

Sometimes, it’s what you don’t see that makes all the difference.

We are a team of engineers who collaborate with clients and the design team to consistently provide the best integrated design solutions. We provide design, consulting and inspection services to customer. We are knowledgeable in the latest industry trends, standards, technologies, and codes requirements.

We provide a holistic design view and evaluate each project and its unique requirements, goals, and challenges, at the initial design phase. Our holistic design approach brings critical decision making to the forefront, engaging the client and entire design team in making decisions to align expectations, improved design and coordination efficiencies while maintaining budget forecasts.

We provide superior client service through honest discussions of the design and construction processes. Our clients have access to the partners and the engineers, each experts in a particular field, and also knowledgeable in all disciplines to best respond to any query.

engineering is a professional service that provides independent expertise in engineering, science and related areas to governments, industries, developers and construction firms. Most consulting engineering services are offered through consulting engineering companies, but are also frequently offered by sole practitioners. Consulting engineering companies can range in size from a partnership of two people to multinational corporations with tens of thousands of employees in offices world-wide.

Consulting engineering firms are responsible for designing and building Canada’s infrastructure which is vital to our social, economic and environmental quality of life. Within a consulting engineering firm, projects are usually carried out by teams that are comprised of a variety of professions and disciplines in addition to engineers and technologists, but the team leader is usually a professional engineer.

Large firms may be able to assemble the entire team from within their ranks, whereas smaller firms may need to partner with other firms to assemble the team. In consulting engineering there are opportunities for engineers and other professionals with a wide variety of technical and personal skills. In a consulting engineering company you will find people with

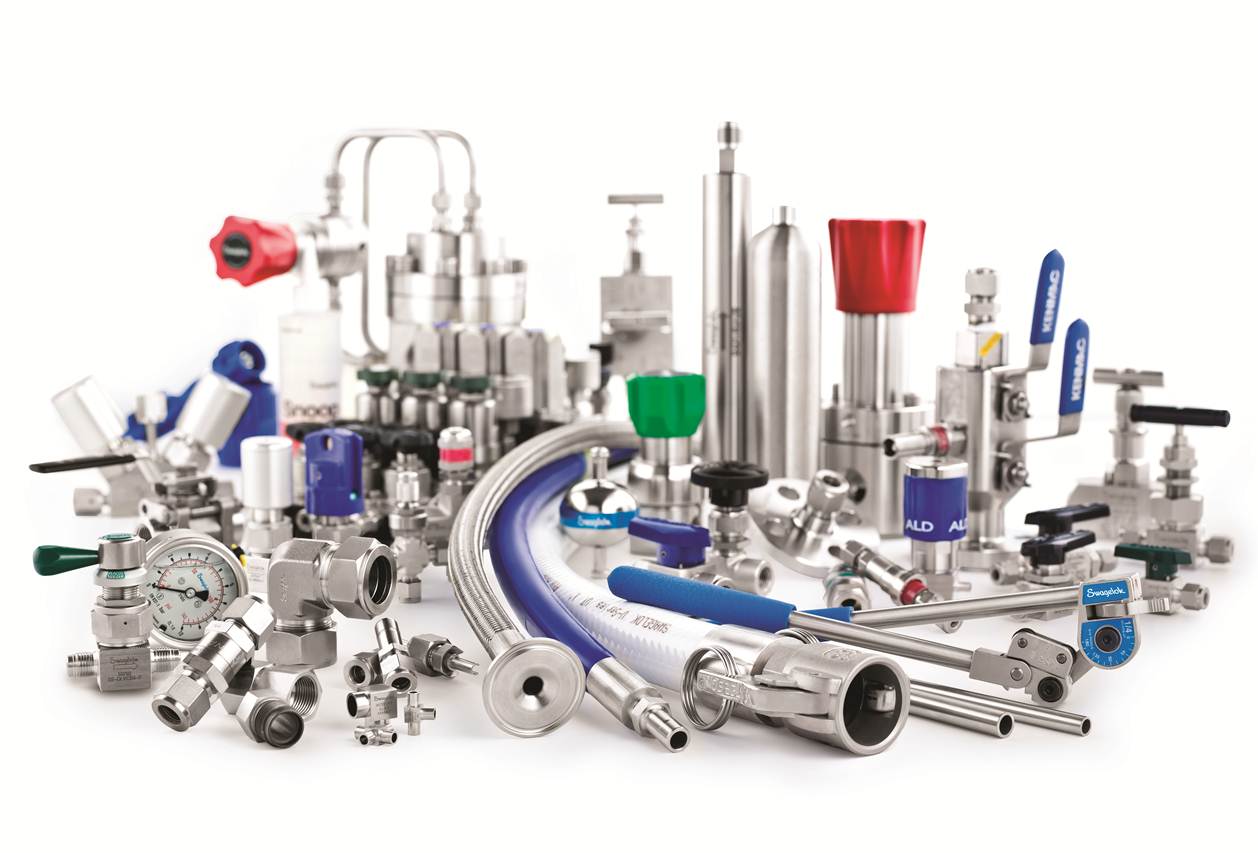

We sell the best engineering supplies, blueprint storage products, drafting supplies, land surveying equipment, measuring tools, industrial equipment, safety equipment, and power tools.. We carry supplies that you buy over and over on a regular basis as needed.